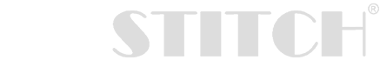

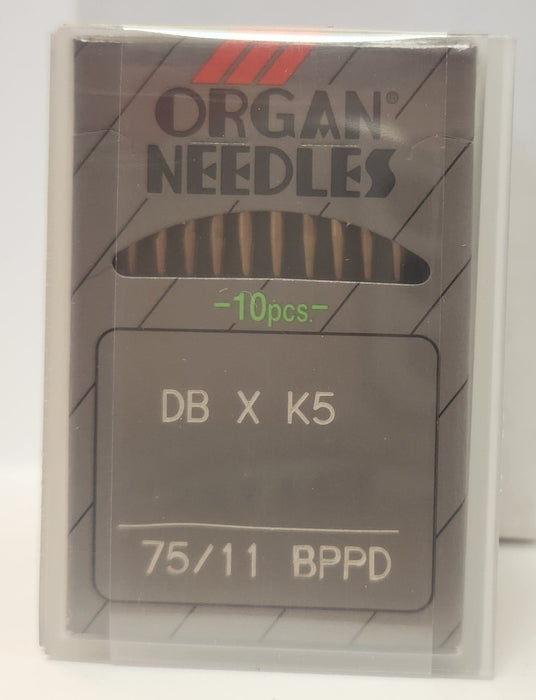

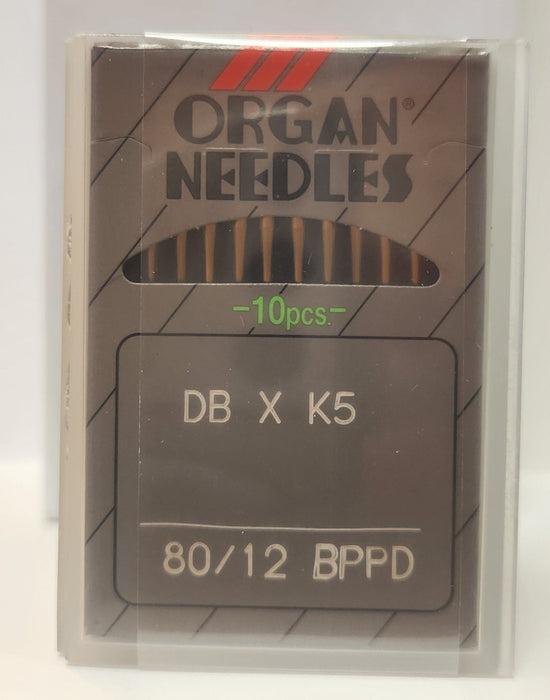

Organ DBK5BPPD | Round Shank | Large Eye | Ball Point | Commercial Embroidery Needle | Titanium | 100/bx

This is a special version of the DBxK5 needles with a titanium coating. These commercial bal point needles will last longer than chromium coated needles.

PD (Perfect Durability) needles have a titanium-nitrate ceramic finish which makes them more wear resistant than any other needles. When embroidering large stitch patterns or penetrating very abrasive, dense or tuff materials, the needle points and suface will maintatin its original shape and demensions 3-5 times longer. PD needle points will not wear down as fast as chromium plated needle points. Use of PD needles gives you longer needle life, fewer defects due to dulled needle points, and increased productivity.

- Organ DBK5BPPD Commercial Embroidery Needle

- PD - Perfect Durability (Non-Stick)

- Commercial Round Shank

- DBxK5 - Large Eye

- BP - Ball Point

- 100 Needles Per Box

Round Shank Commercial Needles -100 Needles/Box

DB x K5 BP PD - Titanium Ball Point (SUK)

DB-K5 PD (Perfect Durability): PD embroidery needles have a titanium-nitride ceramic finish which makes them more wear-resistant than any other needles. When embroidering large stitch patterns or penetrating very abrasive, dense or tough materials the needle points and surface will maintain its original shape and dimensions 3 to 5 times longer. PD embroidery needle points will not wear down as fast as chromium plated needle points. The use of PD embroidery machine needles gives you longer needle life, fewer defects due to "dulled" needle points, and increased productivity.

Ball Point: Ball point machine embroidery needles are designed to alleviate making holes in knit or loosely woven materials. The cross fibers which constitute the knit or loosely woven materials are relatively far apart as compared to those in tightly woven materials. When an embroidery needle with a standard "set" or "sharp" point encounters one of those fibers in penetrating the fabric, it cuts right through the fiber. This creates a hole in the fabric. The ball point needle pushes aside the fiber it encounters in penetration and thereby avoids making a damaging hole in the fabric. (It is also recommended to use the thinnest possible needle for a particular fabric).